Project implementation in the Automotive Industry

Modernization of the machining socket.

Machine transport

One of the key stages of modernizing the machining socket is the safe transport of new machines or those being dismantled. In our company, the Industrial Services team is responsible for this part of the project. Ensuring proper machine displacement to the installation site is crucial to avoid damage and ensure timely delivery. Depending on the size and weight of the machines, specialized transport means such as cranes, low-loader trailers, or specialized vehicles for heavy cargo transport may be necessary. Planning transport logistics and cooperation with machine suppliers and other stakeholders are essential to ensure the success of this operation. In our internal transports, we use forklifts, pallets, rollers, and air cushions.

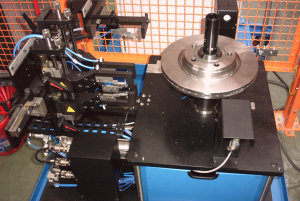

Machine installation and mechanical modifications

Modernization of the machining socket also requires appropriate mechanical modifications, which are carried out by the Industrial Services team. Depending on the machine specifications, work may be required to reinforce foundations, weld, or adjust dimensions and positions of machines relative to each other. Despite precise machine placement according to the plan, it is also necessary to properly adjust fencing to prevent operators from having direct access to the machine work area.

Electrical modifications and control system

The next step is electrical modifications, handled by the Plant Installations department. We ensure proper connection of new machines to the existing electrical system. Depending on the requirements of the new machines’ manufacturer, adjustments to the electrical distribution board may be necessary or connecting new machines to power sources. For machines requiring high power, such as lathes or milling machines, electrical installation work may also be necessary, such as installing new wiring or protections. Before starting up the new machines, it is also important to familiarize with the control, which may require introducing new signals to the control cabinet or modifying the existing control system.

Integration of robot work and machine team

Integrating robot work with new machines is another significant element of modernizing the machining socket. If a robot is already operating in the plant, collaborating with existing machines, it may be necessary to adjust its programs, configurations, or settings to be compatible with the new machines. Depending on the type of robots and machines, adjustments to communication interfaces or protocols may be required to ensure effective collaboration between them. Additionally, adjustments to robot settings and programs may be necessary to ensure effective integration with the new machines.

Comprehensive service

In the process of modernizing the machining socket, the transport and commissioning of new machines are crucial to achieve the intended goal. We carry out all activities in accordance with the manufacturer’s requirements. Safe transport and proper commissioning of new machines require precise planning and coordination of activities, as well as adaptation of existing infrastructure. Our company takes care of all these aspects of comprehensive service, and many businesses have already trusted our reliability and professionalism.