Execution of projects in the food and aerospace industries

Delivery and installation of conveyors.

Customer interaction

We initiate our project process with a detailed dialogue with the customer, where we define all requirements related to the equipment. When designing conveyors, for example, we need to specify the type of material to be transported, its capacity, throughput, distance, and direction of movement. Armed with this information, we develop a project plan, taking into account mechanical, installation, and automation works, as well as adapting to spatial constraints and the client’s budget.

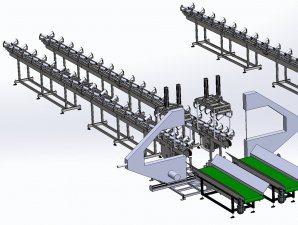

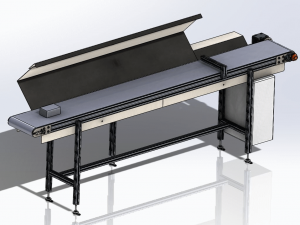

Mechanical design

Our mechanical engineers prepare conveyor designs, considering all mechanical aspects such as loads, structure, drive, tensioning system, rollers, guiding, etc. Often, it’s also necessary to design additional elements such as chutes or sensor brackets, as well as incorporating elements such as couplings, bearings, or springs. For this purpose, we use advanced software such as SolidWorks or Autodesk.

Electrical design

Our electrical specialists prepare the electrical installation project for conveyors, selecting appropriate components such as motors, converters, relays, control systems, or protections. The project also considers safety standards and regulations regarding electrical installations, and the entire system is carefully depicted in electrical schematics. We use professional tools for this purpose, such as EPlan or AutoCAD.

Automation

After consultations with the mechanical and electrical teams, our automation engineers develop a control concept, considering the automation of processes on conveyors. The project includes speed control, direction, synchronization with other devices, e.g., valve islands. Once the automation concept is finalized, engineers prepare hardware configurations and proceed with programming the control according to the established plan.

Implementation

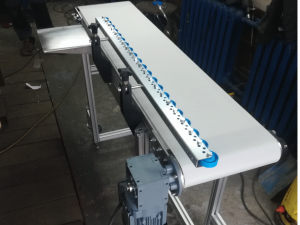

Upon approval of the mechanical, electrical, and automation conveyor projects, we proceed with their implementation. This may involve production and assembly of mechanical components, electrical installation, automation assembly, measurements, and other construction works related to conveyor construction. Upon completion of construction, the conveyors are commissioned, including equipment testing, calibration, any changes in control programming to ensure proper operation.